As the title would suggest, I never had a treehouse bed. Why would this matter to anyone but me? Why write about it and expect people to read it? No this isn’t forced internet therapy, it actually the intro to the treehouse bed I’m making for my son. For all those parents out there who’s eyes have jumped out of their head’s like mine did when I saw the cost of specialty beds, this one’s for you.

Well it all started eight years ago when I married my wife . . . Oh wait, I guess you don’t need the WHOLE story. Sufficed to say we have a son presently, and a daughter on the way. We turned our crib into a big boy bed for our son, but now it must be a crib again. This is the point most parents go buy a bed, or swindle grandfolks into make the purchase. For whatever insane reason, which escapes at the moment, we decided to be cool parents and do something fancy!

Children’s beds must be made of gold plated lumber by German craftsman. At least that’s what the price tag would have you believe. After looking at a few options I decided that a treehouse bed was where it was at. This would accomplish two things. It keeps the bed off the floor allowing for more space, and it’s super cool.

Trying to make a bed from scratch with a pregnant wife and overactive son is fraught with peril, deep concern, and occasionally saw dust in one’s eye. I was able to accomplish several feats for which I shall now discuss. Number one, I fit four ten foot 2×4’s into a 1999 Honda CR-V and was able to close the rear glass hatch. After you recover from your amazement read on. Number two, I succesfully filled an entire corner of my son’s room. Yes, things really are bigger than their drawings. Number three, after all the 2×4’s made it home I got a 4×8 sheet of plywood into the car. I know, I’m a mad genius. Number four, once finished I should be right around the $150 mark. *golf clap*

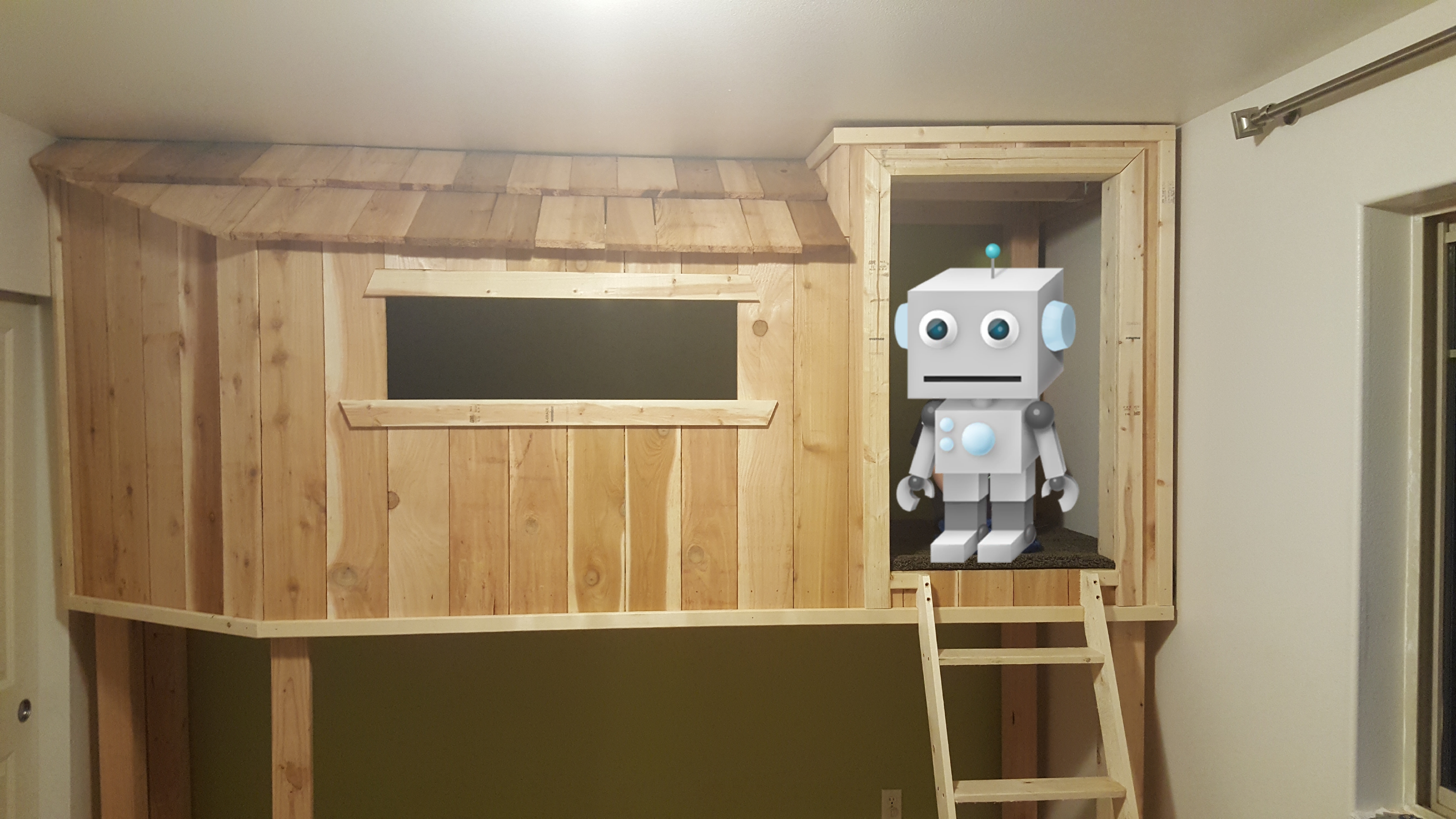

Now that I’ve wowed and amazed with my cunning plus thrift, here are some pictures.

I made it four feet off the ground so we could fit his train table and work bench. The left side tapers so you can get into the closet. On the right the door runs as high as possible to protect fragile noggins. There is a sloped section for a roof to add some flair.

The young master making an appearance. You won’t see him too often because I can’t afford to pay him royalties for his likeness. Here the window is ruffed in and the front wall is done.

Front roof made from cedar shakes. This was a killer to lay out, and it add nothing structural but man does it look good.

Getting the angle here took some time. Once I got one board set the rest were the same all the way up.

Roof is done. Turned out just how it was in my head, which is always satisfying. The doorway is sided and the interior is carpeted with a nice remnant curtesy of Grandma and Pappie. Well they didn’t buy the bed, but the carpet is soft.

Items that are left include framing the doorway and adding trim to various portions. Oh, and a ladder so he can get out. Though I’m still not to sure about it. Maybe a gate instead.

UPDATE 05/17/17

Well, I got the bottom trim, the top window trim and the doorway framed in before I ran out of lumber. One last trip to the hardware and I should have what’s needed to put the bed into service. I might just have to sleep in there myself, just to make sure it’s safe and all. Have I mentioned I never had a treehouse bed yet?

UPDATE 05/20/17

To say I am done would not quite fit, but I can say it is ready to sleep in. Trim is up, ladder is constructed and attached. Phase one is complete. Phase two is painting the trim a nice brown color. Phase three will be adding some lighting and covering the underside with something that looks nice.